News

Power Space tailor-made dust removal plan for you

Understanding the Cartridge Dust Collection Systems

In the industrial sector, Cartridge dust collection systems play a pivotal role in maintaining air quality and ensuring a safe working environment. There are different types of dust collection systems, they are:

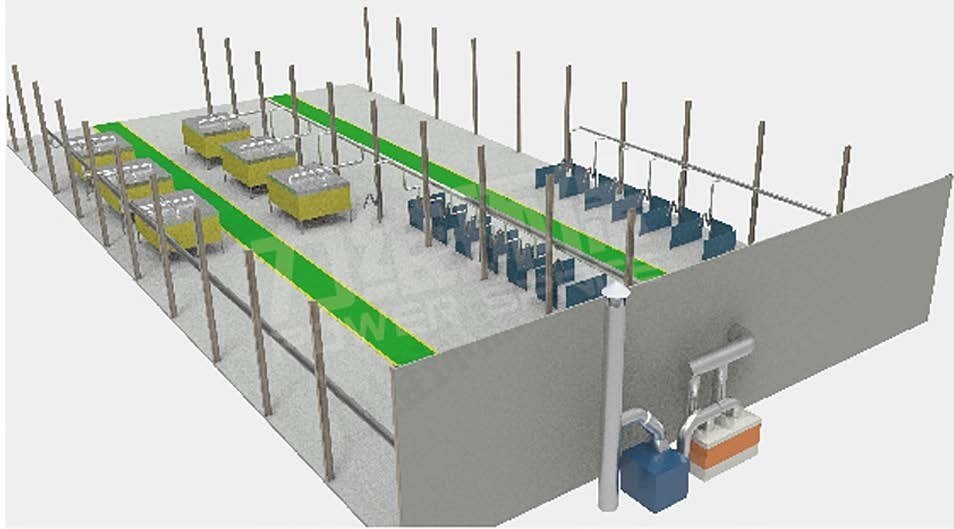

Centralized Dust Collection System

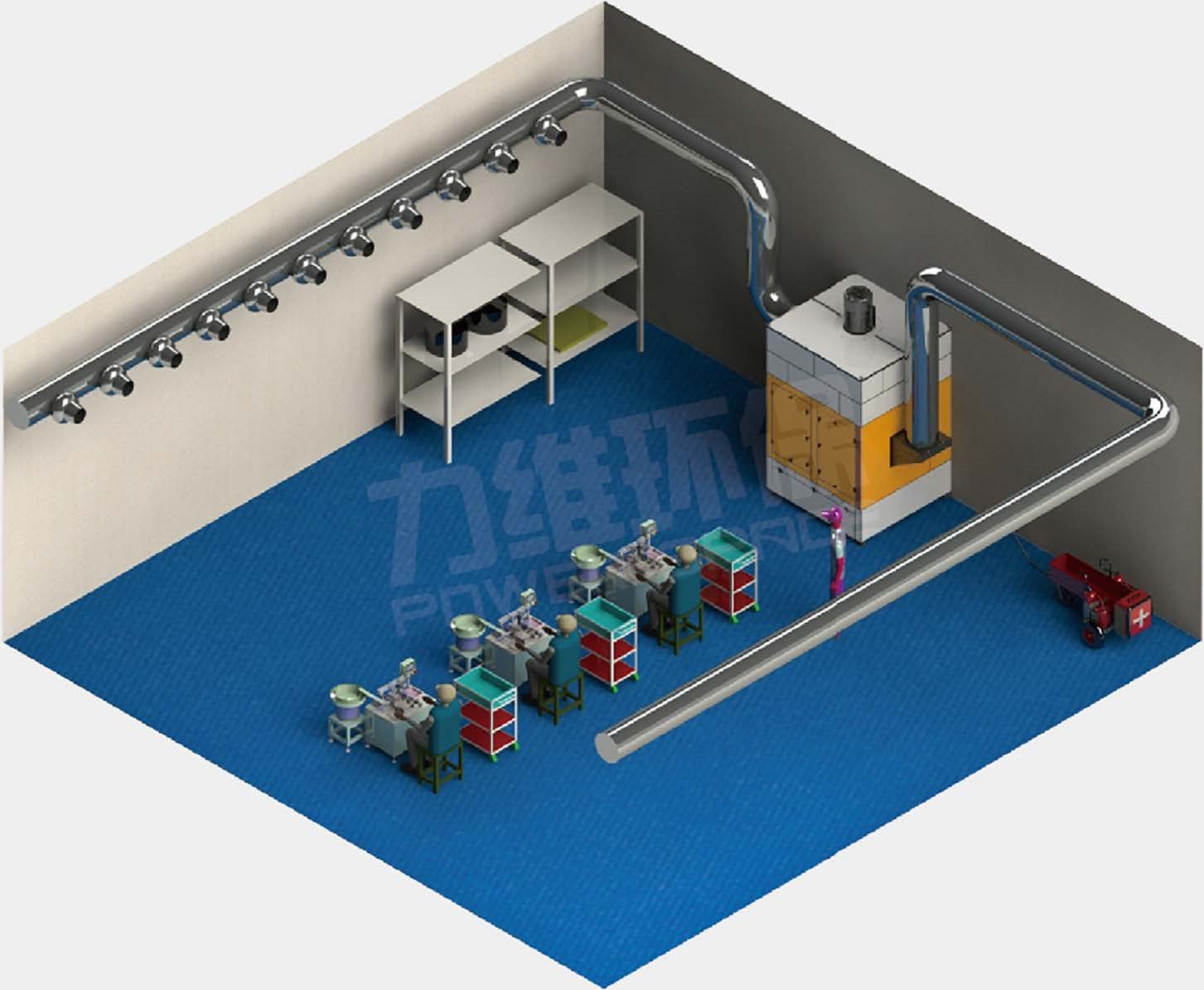

Blow-suction Dust Collection System

This article aims to provide a comprehensive understanding of cartridge dust collection systems, including their types, applications, and design considerations.

Centralized Dust Collection System

Centralized dust collection systems are modular by design, allowing for customization based on the user's workshop conditions. These systems typically consist of separate welding fume extractors, centrifugal fans, extraction arms, hoods, dust collection system piping, and electrical control systems.

Application for Centralized Dust Collection System

Centralized dust collection system is suitable for these work environments:

Multiple welding stations are concentrated;

Welding positions do not change frequently;

Each welding point has a longer duration;

The distance between welding points is short.

Blow-suction Dust Collection System

Blow-suction dust collection systems utilize dust collectors as the power source to effectively collect and purify welding fumes in workshops. In this system, air supply and dust collection system pipes are arranged on one side of the workshop, with a symmetrical layout on the opposite side. The design of the blow-suction system allows for comprehensive coverage and efficient dust collection, making it a preferred choice for complex industrial environments.

Application of Blow-suction Dust Collection System

Blow-suction dust collection system is suitable for these work environments:

Workshops haven't local ventilation,

Welding points are not fixed,

Welding pieces are large in size.

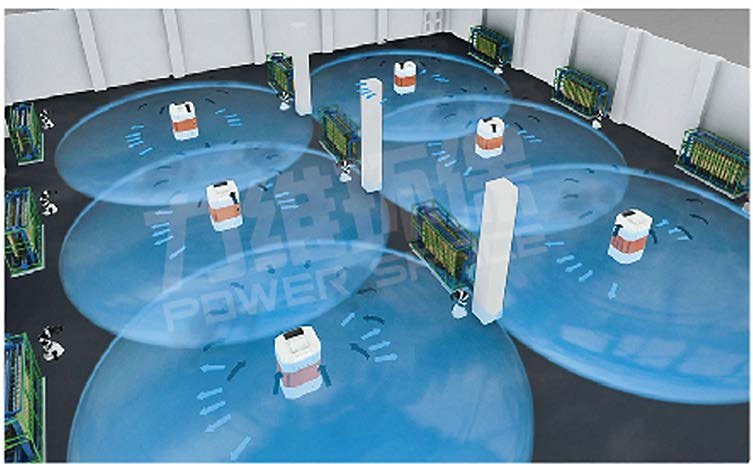

Fume extraction Filter Tower

Fume extraction Filter towers operate on the principle of suspended welding fumes. They effectively extract waste gases containing welding fumes and dust. The design includes a pretreatment system, a purification chamber, and dust collection system piping that ensures clean air is returned to the workshop while filtered dust particles are collected in a dust drawer at the equipment's base. The design of these towers is such that they can be seamlessly integrated into the factory setting, providing an effective solution for dust control.

Application of Fume extraction Filter Tower

Fume extraction filter tower is suitable for these work environments:

Welding points are not fixed, large or heavy workpieces are welded,

The installation of dust collection pipes is not feasible.

Mobile Welding Fume Extractor

Mobile welding fume extractors are designed to address various industrial demands. These energy-efficient, environmentally friendly, and cost-effective devices are ideal for localized welding and cutting fume treatment. They can be selected in different models based on actual working conditions and are equipped with casters for ease of movement and flexibility.

Application of Mobile Welding Fume Extractor

Mobile welding fume extractor is suitable for these work environments:

Welding pieces are small in size;

Fixed-point welding positions;

Dust particles are small during welding or cutting processes.

In conclusion, understanding dust collection systems is crucial for industrial facilities aiming to maintain high air quality and a safe working environment. The choice between large-scale and small-to-medium-scale equipment depends on the specific needs of the workshop. A well-designed dust collection system manufacturer can significantly enhance productivity and ensure compliance with environmental regulations. Power Space, more than 15 years expercience for industrial dust collection system design. If you need dust collection system solution, contact our experts ,and they will help you!