News

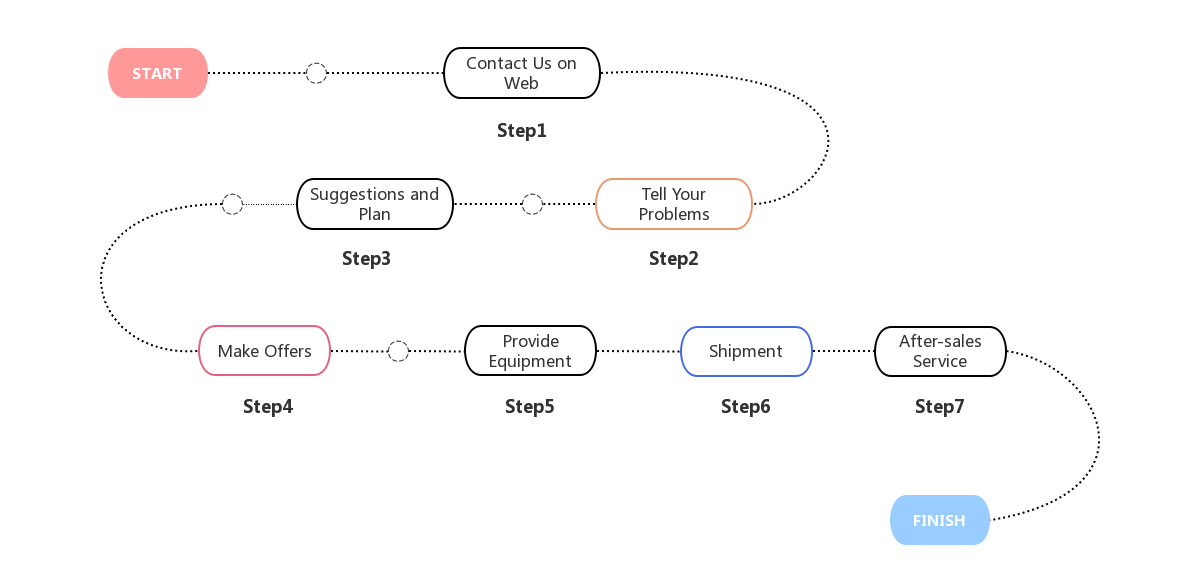

Power Space tailor-made dust removal plan for you

The Working Principle of Welding Fume Extractors

Welding fume extractors, also known as portable dust collectors or welding dust extractors, play a crucial role in industrial settings where welding operations generate harmful airborne contaminants. In this article, we'll delve into why welding fume extractors are essential, examine the components of these devices, and explore their advantages.

1. Why Use Welding Fume Extractors

Welding fume extractors serve multiple purposes, aligning with local smoke emission standards and regulations, enhancing the welding work environment, and mitigating health risks for workers. Firstly, adherence to local smoke emission standards and regulations is paramount for any industrial operation. Welding fume extractors ensure compliance by effectively capturing and filtering out harmful pollutants, thereby reducing environmental impact.

Secondly, these extractors improve the welding work environment by removing hazardous fumes and particles, thus safeguarding the health of welders. Prolonged exposure to welding fumes can lead to respiratory issues and other occupational health hazards. By utilizing welding fume extractors, employers prioritize the well-being of their workforce and create a safer workplace environment.

Lastly, welding fume extractors help minimize the contamination and damage caused by smoke particles to machinery and precision components. Unfiltered welding fumes can settle on surfaces, leading to corrosion and affecting the performance of equipment. By deploying effective extraction systems, industries can prolong the lifespan of their machinery and maintain operational efficiency.

2. Components of Welding Fume Extractors

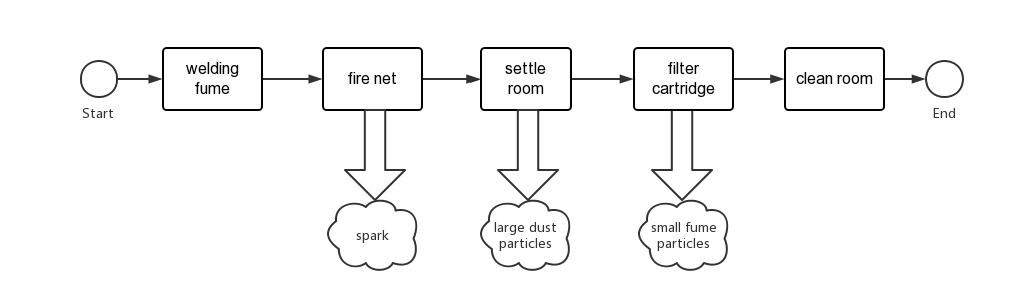

A welding fume extractor comprises several integral parts designed to capture, filter, and expel contaminants. The main components include the suction hood, extraction arm, filter cartridge, and fan. The extractor operates on the principle of airflow induced by the fan, drawing welding fumes through an adjustable suction hood into the inlet.

The suction hood serves to capture smoke and sparks while the extraction arm acts as a transport conduit and an interaction site for smaller particulate matter. Inside the extractor, the filter cartridge serves as the core purification element. As the fumes enter the settling chamber, gravity and upward airflow separate coarse particles, directing them to the ash bin. Meanwhile, the filter cartridge captures fine particulates on its outer surface, allowing purified air to flow through to the clean chamber before being discharged through the outlet.

3. Advantages of Welding Fume Extractors

Welding fume extractors offer several advantages that make them indispensable in industrial settings. Firstly, their portability enables flexible positioning within the factory floor, unrestricted by fixed dust emission points or workstations. Secondly, the utilization of polytetrafluoroethylene (PTFE) coated filter materials ensures a large filtration area, high purification efficiency, and low consumable costs, eliminating the need for frequent replacements.

Moreover, these devices feature specialized control systems for enhanced safety and stability, including high-pressure leakage protection. Additionally, the use of externally balanced extraction arms enables effortless maneuverability in three-dimensional space, allowing easy access to dust emission points from any angle.

4. Conclusion

Welding fume extractors are vital tools for maintaining a clean and safe working environment in welding operations. By understanding their working principles, components, and advantages, industries can make informed decisions regarding their implementation, ensuring compliance with regulations and safeguarding the health and productivity of their workforce. POWER SPACE, the professional mobile dust collector manufacturer, could give you comfortable service. If you have any inquiry, please contact us any time!