News

Power Space tailor-made dust removal plan for you

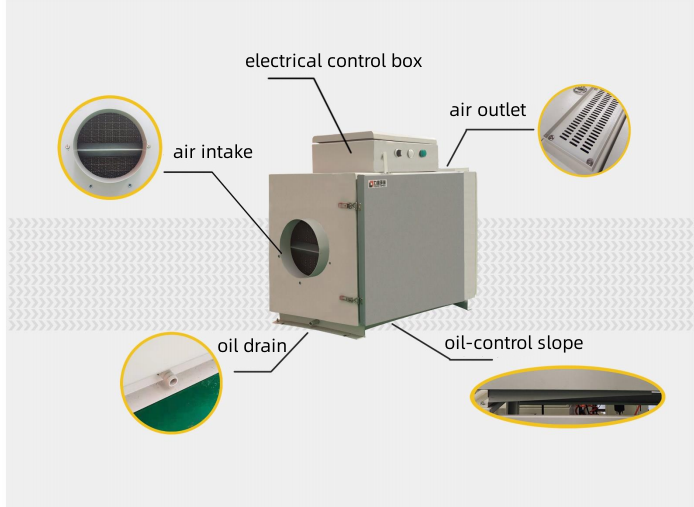

Electrostatic Oil Mist Collector Systems Introduction

Oil mist collector system, also known as industrial electrostatic oil mist collector, is essential equipment used in various industries to effectively capture and remove oil mist particles from the air. These systems help to maintain a clean and safe working environment by preventing the dispersion of oil mist, which can pose health hazards to workers and contaminate the surrounding environment.

Why is oil mist produced in industrial process

In industrial production processes, oil mist is generated as a result of the use of cutting fluids, lubricants, and other oils. There are several reasons why oil mist is produced in industrial manufacturing settings:

Machining Operations: In metalworking processes such as milling, drilling, and grinding, cutting fluids are used to lubricate the cutting tool and workpiece, reduce friction, and dissipate heat. As the cutting tool interacts with the workpiece, the high-speed movement can cause the cutting fluid to atomize and form oil mist.

Metal Forming Processes: During metal forming operations like stamping, forging, and extrusion, lubricants are applied to the metal surfaces to reduce friction and facilitate the shaping process. The mechanical action involved in metal forming can lead to the generation of oil mist.

Cooling Systems: Industrial machinery and equipment often use oil-based cooling systems to regulate temperature and prevent overheating. As the oil circulates through the system and comes into contact with hot surfaces, it can vaporize and form oil mist.

Cleaning and Degreasing: In industries where parts and components need to be cleaned or degreased, solvents and cleaning agents containing oils are used. The evaporation of these cleaning agents can result in the production of oil mist.

Lubrication Systems: Equipment and machinery in industrial settings require regular lubrication to ensure smooth operation and prevent wear and tear. The application of lubricating oils can lead to the release of oil mist into the surrounding environment.

The working principle of oil mist collector

The operation of an electrostatic oil mist collector system involves the extraction of air contaminated with oil mist from the source, such as machining or metalworking equipment. The air is then passed through the filters within the collector system, where oil mist particles are captured and collected. The cleaned air is then released back into the environment, while the collected oil mist is typically drained or disposed of properly.

Which kinds workshop can use oil mist collector

Metalworking Industry: Industrial oil mist purifiers are extensively used in metalworking processes such as machining, grinding, and cutting, where oil mist is generated from the use of cutting fluids and lubricants.

Automotive Industry: In automotive manufacturing plants, industrial oil mist purifiers are used to remove oil mist generated during processes like engine assembly, metal stamping, and painting.

Aerospace Industry: Industrial oil mist purifiers play a crucial role in the aerospace industry, where oil mist is produced during machining, drilling, and other manufacturing processes.

Printing Industry: Printing presses generate oil mist from ink and lubricants, making industrial oil mist purifiers essential for maintaining air quality in printing facilities.

The advantages of oil mist collector

Electrostatic oil mist collector is a device used in industrial settings to filter and remove oil mist, fumes, and smoke from the air, typically generated by metalworking processes such as machining, grinding, or cutting. Here are some advantages of using an oil mist collector:

Extended Machine Life: Oil mist can contaminate machinery and reduce its efficiency and lifespan. By removing the mist, machines can operate more effectively and require less maintenance.

Better Workplace Visibility: Oil mist can reduce visibility in the workplace, which can be a safety hazard. Clearing the mist improves visibility and can increase productivity.

Reduced Cleanup and Maintenance: Without an oil mist collector, the buildup of oil mist can lead to more frequent and extensive cleaning of work areas and machinery.

Energy Efficiency: Modern oil mist collectors are designed to be energy-efficient, which can help to reduce operational costs.

In summary, oil mist collectors are an essential component of a comprehensive industrial air filtration system, offering numerous benefits for workplace safety, environmental compliance, cost savings, and employee well-being. Contact us, find experts at Power Space.