News

Power Space tailor-made dust removal plan for you

How to Choose the Right Laser Fume Extractor for Your Factory

In today's industrial landscape, laser cutting processes have become integral for precision manufacturing. However, with the benefits of laser cutting come the challenges of managing hazardous fumes and particulates. To address this concern, selecting the appropriate laser fume extractor is paramount. In this article, we will delve into the key criteria, selection methods, and recommended best fume extractors to ensure a clean and safe working environment.

1. Procurement Standards: Defining Your Needs

Before diving into the selection process, it's crucial to establish a set of procurement standards to ensure the chosen laser fume extractor aligns with your factory's specific requirements. Consider the following factors:

Fume Type and Concentration

Identify the types of fumes and particulates generated during your laser cutting processes and assess their concentration levels.

Flow Rate and Air Volume

Determine the required airflow rate and air volume to effectively capture and filter the fumes and particulates produced.

Filtration Technology

Understand the various filtration technologies available, such as mechanical, electronic, HEPA, and activated carbon filters. Choose the one that suits your fume type.

Maintenance Costs

Estimate the ongoing maintenance costs, including filter replacements, energy consumption, and routine servicing.

Energy Efficiency

Opt for an energy-efficient system to keep operational costs in check over the long term.

Noise Levels

Consider the noise levels generated by the extractor, particularly if it will be placed near workers' areas. Lower noise levels enhance workplace comfort.

Compliance

Ensure that the selected extractor complies with local and national environmental and safety regulations.

2. Procurement Methods: Making an Informed Choice

Selecting the right laser fume extractor involves a methodical approach:

Assess Supplier Reputation

Look for reputable suppliers and manufacturers known for their high-quality laser fume extraction systems. Check for customer reviews and references.

Request Expert Advice

Consult with experts in industrial fume extraction. They can assess your factory's unique needs and recommend suitable solutions.

Compare Models

Evaluate different models based on your established procurement standards. Compare their specifications, performance, and costs.

Request Demos

If possible, request a demonstration of the fume extractor in action to witness its effectiveness firsthand.

Consider Long-Term Costs

Look beyond the initial purchase price and consider the total cost of ownership, including maintenance and energy consumption.

3. Recommended Laser Fume Extractors

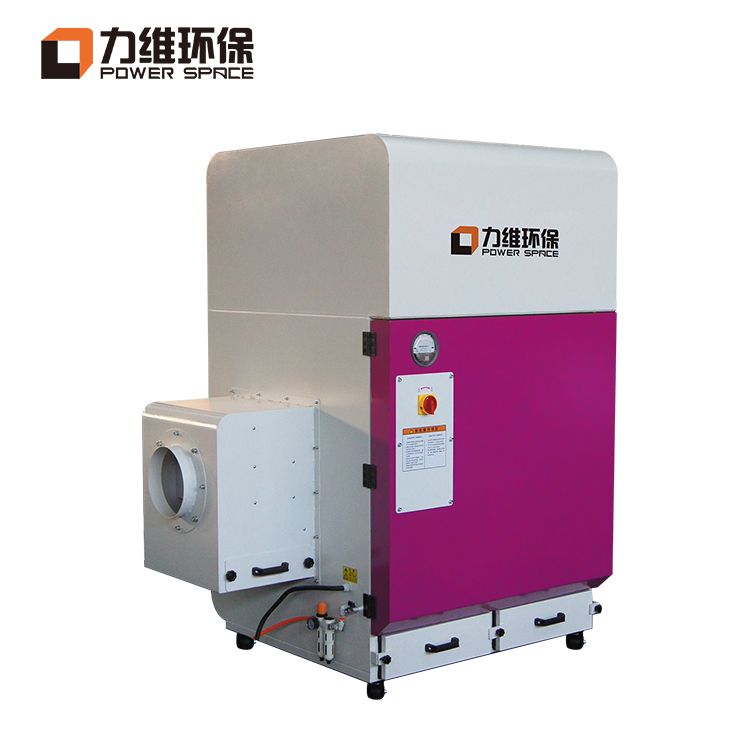

Based on Power Space expertise, here are three laser fume extractors that meet high industry standards:

1. LW1204-055: Energy-Efficient Fume Extractor Solution. If you want competitive price and great power, you can choose this laser fume extractor.

2.LW1206-075: Advanced Laser Fume Extraction System.It has 6 cartridges which remove laser dust quickly.

3. LW1209-110: Best Fume Extractor for Laser Cutting. It is so big because it has 9 cartridges! But if you have this, don't worry dust problems anymore.

These extractors have a proven track record in efficiently capturing and filtering laser cutting fumes, they ensure a clean and safe work environment for your factory.

Conclusion

In conclusion, choosing the right laser fume extractor for your factory is a critical decision that requires careful consideration of your specific needs and diligent evaluation of available options. By adhering to established procurement standards and methods, you can make an informed choice that promotes worker safety and operational excellence.